Time to move on to the door. As has been stated previously, a swinging double door was never going to work. As the two door swings open, the hypotenuse of the two doors will cause the two doors to collide. This is similar to placing a board into an opening, where the board is exactly the length of an opening, but doing it at an angle. The thicker the board is, the harder it is force into place, if it can be done.

Lego is extremely precise and thus counting on any slop is not going to happen. The thickness of the door is composed of a plate and a tile. This only makes the situation worse. One way around this is to open one side first then the other once the first door has cleared. In house construction, where to double doors are designed to work simultaneously, the edges are often beveled to make this work. Beveling in Lego at this scale, is not practical.

So I moved on to sliding the doors. Where the doors are now, that is not possible. The doors have to move back from the front so that there is room.

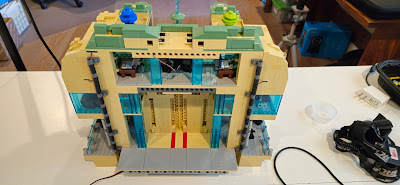

This picture shows the current configuration. The doors are going to have to move back at least 4 studs. The conduit is going to have to change and the back platform will have to get wider.

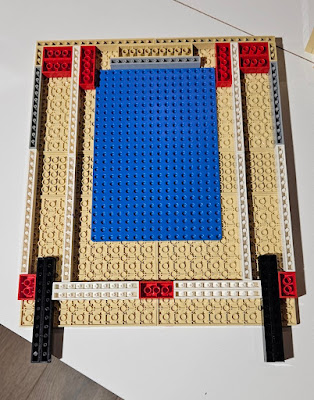

In this post, I showed a prototype of the door mechanism. The total depth needed is 3 studs. The door takes up one stud width, which will accommodate the plate and tile thickness of the door. One stud width is needed for the support wall that contains the driving gear. Finally one stud width for the final gearing mechanism, that contains the work drive.

I started playing with this, trying to understand what changes were going to be needed.

That led to providing more support structure.

Which ended up here. But this was not going to work, since the worm drive sections and the motor had to go in here also.

After several iterations, I ended up here. Though there will probably be more support in the form of some panels added. Also the battery needs to slip under here and power still needs to be added, so I suspect some more changes will be implemented.

Backing up one step, I first tried to find the best implementation of gearing. The small 12 tooth double beveled gear is in a fixed position and cannot move. The gear itself could change, but the position cannot. Also the wall it is attached to represents the edge of the opening, so I dont want this gear sticking out too much. The worm gear to 24 tooth gear can move some. but the black double technic brick support brace cannot move. So that limits its movement. What is shown here is a 36 tooth double beveled gear. I used half spacers behind to line up the gears. Once I achieved a working system, it was time to determine the exact implementation.

This shows the orientation of the gears. There is a small support structure built around the gears. The clear worm drive on the left will eventually be replaced by a black one. For cosmetic reasons I added the curved enclosure around the gears, that was slightly improved in the photo below and the slope parts.

This is mostly finished, just not up on the blocks to achieve final height. The top portion was also changed to add a guide for the doors.

Still some testing to do and then checking the storage box and finally the connections with other modules on the sides and in front. Once that all verifies, I will finishing adding the power and the lights.