The Space Port module was next on the list to be rebuilt and the controller moved inside. This includes completely rewiring this for lights and a motor.

There are LED lights on both sides of the first floor. Also there are lights in the control tower. One side will have two LED controls plus power. The other side will have the equivalent two LEDs plus the LEDs for the control tower. Here we run the wires from the controller over to where the axle goes up to the radar antenna. By using the far hole, I can keep the wire under control. The 1 x 2 modified plate with pin hole (part number 11458) is used to route the wire.

This side had the motor, so it was a little more complicated, plus it had both the two LEDs plus the control tower. I added the 1 x 6 technic brick to help route the wires and keep them away from the gears. This also shows the single motor approach and gearing. This is minimal gearing down, the rest of the slow down is handled by the PWM function in the Brick Buddy.

This just shows where the controller ended up.

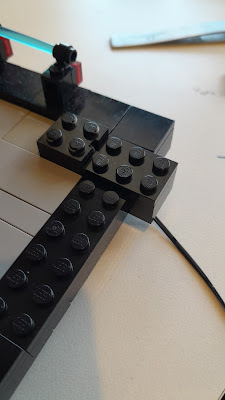

This shows how the motor cable was routed. It is mounted underneath the 2 x 4 plate. This holds the cable in place and keeps it from moving.

And the how the wiring connected to the Brick Buddy.This is the back 2/3 of the bottom floor with the flooring installed. Also noticed how the exhaust grills are recessed. I particularly like this look.Now the support for the radar towers is built up. I have changed the back since eventually there will be a path through the rock wall and into the hanger space.

This gives a better view of the back.

A view from the front.The remaining bottom flooring and walls are now installed. This part has not changed from the original, other than using module build techniques to be able to easier take it apart.

This composite shows how the wire comes up from under the flooring, through the radar tower support and then across the ceiling (not shown). I used a 1 x 2 plate with pin hole to guide the wire a way from the axle. It will then pass through the top of the wall.

Here is the completed first floor with all the walls.

This is how the LED lighting wiring was installed. Again I use the 2 x 2 plate with pin holes and a 1 x 2 plate with pin hole to guide the wiring.

After building the cliff wall with the entrance built into the cliff, I modified the back slightly to have a better physical interface.

Completed Space Port, at least for now.