I finally got around to working on this again. When I first did it, parts availability just killed it. There were several parts I could not get, including the processor. I first discussed this here and then a few months ago here, where I discussed a lot of issues with the firmware. Now that has changed, I went back to it. I made some changes to make it more closely line up with what else I was doing.

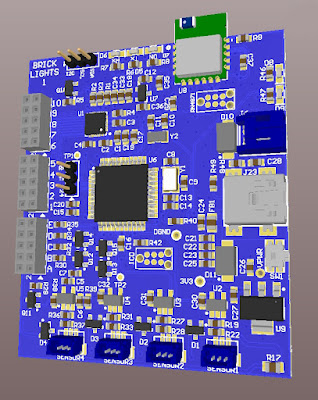

As a recap, this was the first iteration. It has a larger BT module and individual LED connectors. Looking at the picture at the top, you see that the LED connectors have been consolidated down to three 2 x 5 connectors, which is what I use on the Brick Buddy 3. Also I have added a standard power connector. This allowed the entire PCB to shrink down to a 6 x 7 stud size instead of the 6 x 8.

Once I finished this, I sent it out to FAB at my usual fabricator in China. This right before all the tariff stuff blew up. I am sure I was not the only one that was trying to squeeze in under the deadline. Well the PCB that came back had a short between 3.3VDC and GND. Not good. After going back and forth with the vendor, they said they found a place where the tolerances were not met. How they missed it, they never said and how my design software did not flag is also a mystery. Any way drilling out a via fixed the issue.

It required that I put a jumper wire in to power up the section that the drilled out via cut off. So went on and slowly assembled it one section at a time. In the very next section, I found another short this time in a signal to GND. I was not successful in drilling this via out and I called it quits on those boards.

So I started looking at US sources, the only one that came close was OSH Park. But that is 3 PCBs. So I waited to see how this whole tariff thing was going to play out. The downside to OSH Park is that they do not want inner power planes in negative. Which has been the standard for years. I guess toomany instances where the fabricator thinks it is an inner signal layer and does it as a positive. I redid the inner power planes as signal planes and polygon pours for the power/ground. We shall see how this works.

Finally it looked like the tariff stuff settled enough, I went ahead and ordered new boards using the signal layers instead of the power layers.