Here you can see the controller sitting behind the Space Gun, this was never going to work.

This is what the inside of the Space Gun looks like. Being able to place a 4 channel motor controller in this space was not going to happen. One of the approaches I have been working on is using 5VDC to power the motors instead of 9VDC. Neither the original LEGO motors nor the Ebay replacements seemed to have an issue using 5VDC. Don't know the long term effects. I could not find anything during a quick search for this.

This book has been a valuable resource for ideas. One of the great resources in this book is a table of gear ratios for the different gears. After consulting this table, it was time to move to a worm gear. They can give the largest gear reduction.

These three pictures show the prototype implementation. The worm gear drives the 24 tooth spur gear. This in turn will drive a the small 8 tooth spur gear which finally drives the 400 tooth spur gear. This gives a total reduction of 120:1. Plus the 5VDC power input, this seems to make the right speed for these turrets. The 40 tooth gear is held in place with two Technic, Axle and Pin Connector Hub with 2 Axles, #27940. captured between two 1 x 2 bricks with axle holes. The next issue will be placing the 40 tooth gear at the same height as the driving 8 tooth gear. This is done by placing two Technic Bush 1/2 Toothed, Two Interior Ridges, #4265b on the axle. This spaces the 40 tooth gear at the correct height. Then another spacer keeps the gear down.

This shows the final implementation in the module. I kept the turntable for the main Space Gun. The turret is too large and unwieldy for the smaller turn table.

This picture shows the arrangement. I used the 12 tooth double beveled gear to drive the turntable.

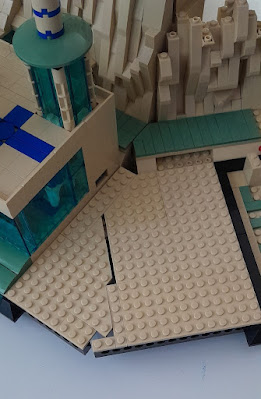

Here is the complete module base with the three motors installed.

And this shows the module base with the controller installed and the motor cabling installed.

I can not place even the small turret on the 40 tooth gear. The axle needs to be supported on both sides of the gear. Thus I use a small turntable. What you can not see is the four 2 x 2 jumper plates in the placing the turn table hole in the correct space. The hole needed to be offset 1/2 stud in both X and Y. The L shaped plate shows where the axle will go through. Instead of running the LED wire the entire depth of the module, to the back where the controller was, I now go through the top as soon as possible. I originally was going to use a 2 x 4 technic plate with holes, but those holes are not big enough for the 2 pin connector I am using. I created a 1 x 1 hole for the connector to pass through.

These two pictures show how the area is covered.

More in the next installment.