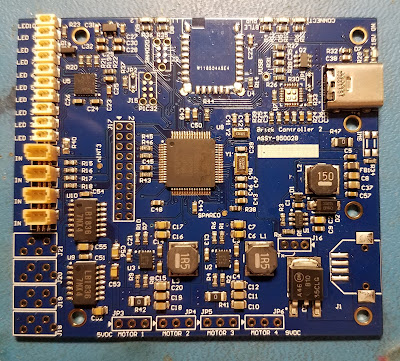

I thought I would get a head start on the firmware for Brick Buddy 3 while waiting for the PCBs to arrive. I would use the Curiosity HPC development board I had originally used in the Solar Shed project. The HPC is on the right.

This is the only development board I have that would hold a 28 pin PIC. I decided to just go with a PIC18F46Q71, which is the 40 pin version. The attractive part is the two Mikroe Click sockets on this board. One could be the RN4871 Bluetooth module and the other would some generic I2C Click board (I2C EEPROM memory) so that I can work out the I2C driver. This was also driven by the need to check out the new common libraries I discussed earlier in this post. The Q71 family has the improved full featured standalone I2C module instead of the standard MSSP that has been in PIC18F for a very long time. The PIC18F Q71 offered great PWM capability, 28 pin SSOP, good amount of memory ( FLASH and RAM) and some other goodies that escape me now. Oh and I could buy it.

And the fun begins. There are now two versions of this Curiosity HPC.

All of the Curiosity boards have built in PICkits. Well version 1 ( what I

have) is based on PICKit3 and the version 2 on PICKit4. And wouldn't you

know it, version 1 of the HPC will not support the PIC18FxxQyy

devices. No biggee, there is a 6 pin ICSP header. I removed R13, R14,

R15 which were the resistors on PGC, PGD and MCLR. These three

resistors connect back to the built in debugger. Removing them isolates the built in debugger hardware. I soldered on a 6 pin header to the ICSP pads, connect my PICKit4

and I should be good.

Well that was awful naive of me. First off only the latest versions of

MPLAB X will program these chips. The earlier versions were happy to

compile the code, but connect to the PICKit4, not happening. So I

downloaded the latest version MPLAB X 6.05. It connects, blank

tests, reads the memory, but when you program/debug it just hangs at the

programming the configuration memory, which is the first memory area it

tries to program.

This mess started last week. I tested another 40 pin dip I had

(PIC18F46K40), no issues. So the connection is good. So I must have

damaged the PIC18F46Q71. What else could it be.

I was not smart enough

to order two PIC18F46Q71 parts when I ordered the first one. So another Digi-Key order and wait

for arrival. Side note: USPS delivered in 3 days, 1st class.

I then started again. And the same result. Posted in the Microchip

Forums, not much help. After trying all kinds of stuff, I finally went

to another computer. Maybe the computer is corrupted. But instead of

version 6.05, I installed the supposedly buggy 6.00. And it works.

Went back to the original computer, removed 6.05, installed 6.00 and it

works. For grins, I re-installed 6.05 and it still doesn't work. So not

sure what the definition of "buggy" is anymore.

At this point I claimed victory and will just stick with 6.00 for this one

project. Filed a case and updated the forum with my results. Maybe it

will save someone else the hassle.

If you have acces to the Microchip forum and want more details, search for "SOLVED : PIC18F46Q71 will not program"

More than I thought to just get a simple development board up and running, but that seems to be always the case.😊