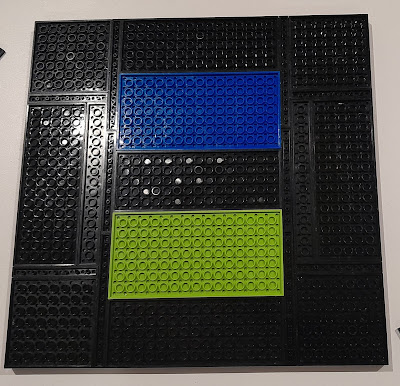

This is where we started.

This is where we ended up.

Again they are basically the same on the outside. There were significant changes on the inside. As in the Vertical Generator, we really started here.

This one took much longer to redo than the last one. And it still needs some cleanup.

The first issue is just how slow can I make the motor turn with a PWM input. I have never been happy with the approximate 1100 Hz that LEGO used in its design. One it makes a lot of noise. The PWM frequency will resonate and if a PWM frequency in the human audio range is chosen, you can hear it. The lowest PWM value is about 50%. Below that it just hums at 1100 Hz. All of the other motor PWM designs I have done in the past, including a fishing trolling motor, I used 15 KHz or higher. That way only the dogs could hear it.

Motor speed on the space guns on this module is important. They can't just swing from one side to the other. It has to be some slow movement that looks controlled. When testing at 50%, they were moving faster than I wanted.

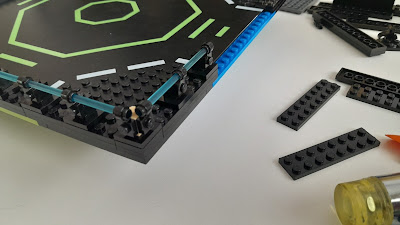

The gear reduction on the left is for the space guns. Some of this was driven by where the motors had to go and also to make space for the Brick Buddy 3 controller. Independent motor control was not important. Thus we have a long shaft that runs the length of the module. This drives the two Space Guns in opposite directions.

The Horizontal generator on the other hand could go quite fast as does the two vertical cylinders. The speed control provided by this gearing arrangement was more than sufficient for what I wanted. The gears on the left in the above picture power this set of features.

This shows the Brick Buddy 3 about to be put into place. I have run the motor cables through the module. And have run the power to the AUX port to power the Brick Buddy 3.

The Brick Buddy 3 is in place now and the motors are connected. Most of the covering is also in place. Unfortunately I will have to remove some of this when I run the wires for the LED lighting.

The first LED Lighting is in the control room area. I added three LEDs that were not there before. This LED is behind the control room and will light up the area directly in front of the generator. This module was always dark until the generator turned on. I never liked that and this changed is meant to correct this issue.

In the control room I added two LEDs. One is white and one is red. My thinking is that in the beginning, the white LED will be on. When the generator starts to spin up, the light will changed from white to red. The picture also shows how the wiring runs between to 1x1 round plates to the other side.

You cannot see it (by design I might add) the wiring. It runs on the right side behind the three 1x1 round bricks. The round brick on the far right side is concealing a small gap in the wall that the wires run down.

Here you can see the gap at the very top of the picture. This runs down to the Brick Buddy 3 using the PCB connection device.

This shows the LED wiring for one of the Space Guns. The wire runs down behind and the underneath the two cones. This design keeps the wire tight to the back of the Space Gun. Then it runs underneath the plate and between two 1x1 round plates. This keeps the wiring centered on the Space Gun.

These two pictures show the wiring going into the wall, between to 1x1 round plates. The space between the two plates is quite large and allows for wiring to run in between. The picture doesn't show it very well, but the hole in the wall is directly behind the Space Gun. This allows for minimal service loop to allow the gun to rotate. While the wire might look like it is close to the gearing, there is actually quite a bit of distance.

For now I am continuing to use the pulley system. This allows for slippage when the Space Guns reaches the end of its travel and the motor is sill on. I have tested the motor connection to the sensor in the scripting language. When the sensor is activated the motor is either stopped or reversed. Once I wire this up, the pulley could change to a gear, though I like that the gears/motor are not mangled. That comes with a price though, changing the rubber band is not easy at this time.