Before the Billy Bookcases could be placed, I needed to figure out a method to secure these bookcases to the wall. Anyone who has ever assembled a Billy Bookcase knows that the back of the bookcase is essentially a very high density cardboard. This back slides into the back of the bookcase in slots and is secured by nails into the top, bottom and middle shelf. However using this to secure the bookcase to the wall is not practical. IKEA provides L brackets for this purpose. |These are attached to the top and connected to the wall. But these will not work for a built in look.

The gap in the back is about 1/2" and with 1/2" plywood undersized these days, the fit was just perfect. I cut plywood the exact width and 3" wide. Any width will do, you just need enough room to be able to get a tool under the shelves to drive the screws into the wall. I started by marking the center of the shelf on the back as shown here.

Then I attached the plywood backer to the shelf using construction screws as seen here.

Finally I used a nail gun to secure the sides of the bookcase to the plywood backer.

What this does is provide a place to secure the bookcase to the studs in the wall just like any other cabinet would be attached.

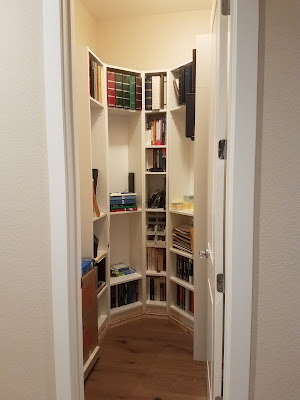

This solved securing the bookcases to the walls for the three bookcases that are flat against the wall, two 15" bookcases on either side and the 30" bookcase. But the two 15" bookcases that are on 45 degree angles and the highly customized one in the center back, this wont help. The two 45 degree bookcases only touch the wall on their corners and the highly customized on is 9 3/4" wide which is between the studs.

I went through several ideas. My first thought was to build a triangular frame out of 1x4 that would attach in the corner. The bookcase would attach to the hypotenuse of the triangle. The major problem with this is Sheetrock corners are not perfectly square. I spent several days measuring, remembering what I learned in geometry and trigonometry and then measuring again. This would have lead to multiple issues of trying to align the bookcases. So I gave up on this idea after a thorough mental exercise. I briefly played with a similar idea using a triangular piece of plywood, thinking this would be easier to match the Sheetrock corner. I gave this up when I could not figure out a method for keeping this parallel to the floor. (The triangular frame had the same problem, but weighed less than 1/2" or 3/4" plywood.)

The method I settled on was to connect the bookcases to the floor and to the next book case. Here is the beginnings of the floor connection.

This method is composed of these parts. A triangular piece of plywood (45 degree right triangle) used at the bottom and at the top (more on this later) and 1x4 piece of lumber. The 1x4 is ripped down to the correct height to fit under the bottom shelf. The length is about 12" which is 3/4 the width of the shelf. Needed some wiggle room during placement. I placed this in the center of the bookcase and where I could attach to the frame I built on the floor. Also wanted to minimize the exposure of screw heads, hoping that whatever was placed on the bottom shelf would cover the screw heads up.

Next is a triangular piece of plywood that is attached to the floor frame and placed up against the bookcase attached to the wall. This creates a "stop" that the 45 degree bookcase presses up against. What I determined was without this, the bookcase would slide around and positioning it became difficult. This piece of plywood provides the necessary support to keep the bottom of bookcase in place.

But as you can imagine the top of the Billy bookcase is moving around. The obvious answer was to place another triangular piece of plywood near the top. These two pieces, at the bottom and top create a wall that the 45 degree bookcase is position against. Connecting the bottom piece was easy, the top I had to get more creative.

I started with identical pieces at the bottom and the top. I decided to attach the top piece using the top shelf support hole in the Billy bookcase. This hole would provide consistent placement from bookcase to bookcase, since these Billy Bookcases are now completely made by robots and CNC machines. This required drilling a complimentary hole that did not exist, for whatever reason the top two holes are missing in the back. I used 1 1/2" Truss type screws with sharp points.

I then drew a line that was 3/8" below the two holes and checked it for level, which it was. This line is the bottom of the triangular plywood support piece, which is 3/4" thick.

Now I did multiple dry fits, to understand where the plywood support piece needed to be. Positioning this is critical since the edges of the two bookcases need to just touch and the plywood support piece slides in so it will pull the two bookcases together. I inserted the screws until about 1/8" of the screw was exposed on the outside of the bookcase. Then I carefully lined up the plywood support as I had done in the previous dry fits and pressed it against the outside of the Billy bookcase. This made two slight impressions as seen below.

Then I drilled pilot holes for the screws. This made aligning the plywood support piece easy and then the screws pulled it tight to the bookcase. Checked for level and perpendicular to the bookcase, all good. This method was devised for one person, if you have competent help, you can probably do this a lot faster. Here is what it looks like.

Once the top triangular support piece was in place on the adjoining bookcase, I prepared the holes in the 45 degree bookcase at the top and in the bottom, then set it in place. A little struggling with placement, screwed the bottom to the support with two construction screws and then the two Truss head screws at the top and it was in place. Rinse and repeat and I am ready for the highly customized bookcase at the back wall.

Next I tackle the bookcase at the back wall.