When I first started the Space base, I had a general idea of the color scheme, but did not have all the parts in the correct colors. Using the standard color terms, this is what I envisioned in the beginning:

The base "base" is BLACK.

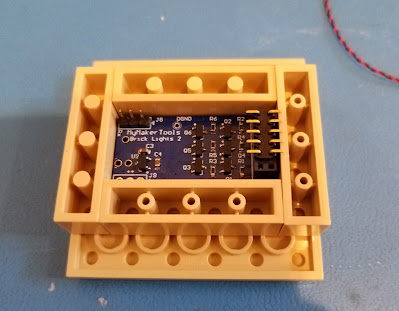

The majority of the structure is TAN.

The sturucture accent is SAND GREEN.

The individual section accent is SAND BLUE.

All of the glass is TRANSPARENT LIGHT BLUE

The interior flooring is LIGHT BLUISH GREY

The interior support structure is BLACK

The two BLACKTRON II brigade colors are TRANSPARENT BRIGHT GREEN/LIME (always on the left) and TRANSPARENT DARK BLUE/BLUE (always on the right).

Other colors are used, but are mostly muted colors as to not distract from the above color scheme.

Here are some of the changes that have happened.

This

this

has changed to this

this

has changed to this, but the two black dishes need to be changed to SAND BLUE. Unfortunately that color is not prolific and I am waiting on the next collection of parts needed. That way I can defray the shipping costs, which are only going up right now.

This is the base design. I have two more to do, since I added the last two sections that make the Space Base a little over a semi circle now. Usually these designs come to me while I am doing something completely else.