With the angles decided, I could work on verifying that the wedge plates are in the correct place. To extend the angle line, the plates have to in certain places. Otherwise the edge line will parallel, but not contiguous. I learned this the hard way.

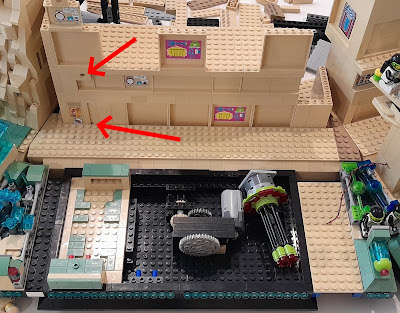

The cliff module on the left is a standard rectangular module. The one on the right has the angle on the left side and a detachable module to form the angle on the right side. This detachable module is needed to maintain the ability to fit in the standard container.

Now I working on the backing hanger space. At first I thought the two modules would each a straight side and angular side.

Here you can see the left module and its angular side and the straight side on the adjoining module.

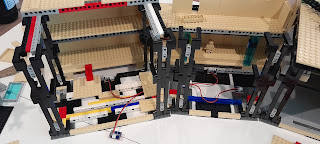

These two pictures show the left module finished and the beginnings of the right adjoining module.

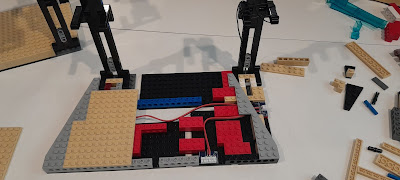

But that idea did not last. It became obvious that assembly of the display would be easier if the right module had both angular sides. This was especially true when having to build the second floor and the top of the backing hanger space. And the right module, was a standard rectangular module. This picture shows the prototyping of this concept.

Here is the two modules in the process of determining where the wedge plates will go.

These pictures show the final determination of the wedge plate placement.

Here the left module is basically finished and the right module is almost complete. This is the final fit check.

Here is the left module base is finished.